A reliable source of energy is essential for the proper functioning of an automobile. Whether it’s the volume of accessories that ensure passenger safety and comfort, or the powertrain controlled by electrical and electronic sensors and actuators, they all consume electrical energy.

The battery that stores electrical energy will quickly run out without the help of the alternator that supplies it with energy when the engine is running.

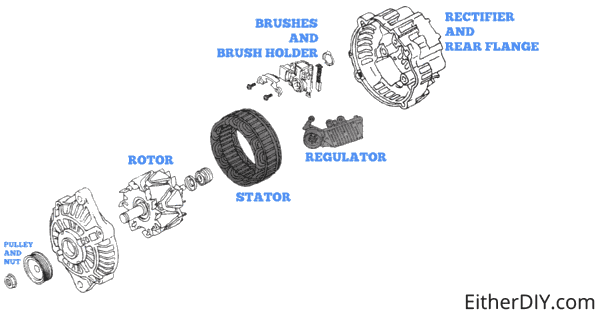

Car alternator Components

The alternator and the battery are the main responsible for the car charging system, that’s why it is sometimes difficult to recognize the defective element during a power failure.

Let’s see the role of the alternator components and the alleged failure of the system.

Modern alternators are mainly composed of these elements. Pulley, front flange and rear flange. Rotor Stator Regulator Rectifier

Alternator rotor

All modern alternators are equipped with a rotor, powered by two carbon brushes at its slip rings which excite it to produce a magnetic field.

When excited, the rotor becomes an electromagnet thanks to its air gap wound with hundreds of turns of wire and then coated with varnish inside the rotor claws. This coil is in relation only with the slip rings of the rotor which receives the current of excitation by the brush holder nowadays integrated in the regulator.

Stator of the alternator

It is the stator which produces the output current of the alternator. It is made up of rings of laminated sheet metal which prevents the production of eddy currents that could be generated by the speed of rotation of the rotor in the center of the stator. The number of coils in the stator represents the power of the alternator.

The rotor, which has become a magnet after its excitation, rotates inside the stator, like a magnet inside a coil, which causes a displacement of the electron and the production of current in the stator.

Voltage regulator of the alternator

The most complex part of the alternator. The integrated electronic voltage regulator is of the hybrid type when we find on the same ceramic plate: resistors, capacitors, transistors, etc. It often integrates the brush holder.

The role of the voltage regulator is to maintain a stable voltage at a predetermined value regardless of the engine speed. Without it, the alternator could reach values that damage the battery and the car’s electrical accessories.

Rectifier of the alternator

Since the current coming out of the stator is alternating, it should be changed into direct current, this is the first job that the rectifier performs by means of diodes.

Secondly, it prevents battery discharge through the three-phase stator windings, i.e. it allows the current to flow from the alternator to the battery.

know Symptoms and How to Fix

Voltage test

Get a digital multimeter. Start the car, then stop it with the handbrake and put the gear selector in neutral or park. Turn on the multimeter and set the multimeter switch to 20V DC. Measure the voltage at the battery terminal with the com line at the - terminal and the v line at the + terminal. You should get a reading between 13.8 and 14.4 volts. If the reading taken is not within this range even at the current output of the alternator you must overhaul or change it. The stator or the rectifier may be the cause.

Test of magnetization

With the engine running take a piece of metal usually a wrench attached to a wire approach the alternator pulley and check that the pulley is well magnetized. If not, either your rotor or brushes in some cases, the rectifier is also defective. In normal condition your charging light on the dashboard should be on.

Audible test

Either the alternator belt or if your vehicle has a single serpentine belt, don’t ignore the squeaking under the hood. This could be a loose or worn serpentine belt that is not transmitting engine speed to the pulleys. Make sure your belt is tight.

Leakage current test

All modern vehicles contain at least a 0.050 Amp leakage current that never exceeds 0.200 Amp that powers certain electronic components. To check that yours is normal, turn off the engine, turn off everything inside the car and close all the doors. Disconnect the hood open indicator plug if there is one. Change the red plus side of the multimeter to the A ammeter and then disconnect the negative (-) terminal of the battery. Place the ammeter between the negative battery terminal and the car’s ground. If the reading is above 0.100 Amp you have a ground at the car.

Generally it is a defective rectifier that is the cause your alternator to be sure disconnect the alternator from all its connections and then redo the test.

Battery Test

If all the tests of the alternator are successful and the charging problem still exists, here is the last one: Have your battery charged and take the voltage at its terminals after 12 hours or more after the change. If the reading is below 12.4V with no terminals connected to the battery, it must be replaced.

Which Alternator for Your Car

In case you have to change your alternator, replace it identically here is a path that will help you know these characteristics like a pro!

- Go to piecesauto24: Click on “select vehicle”.

- Choose the brand

- The model and the year

- The engine

- In the spare parts catalog you choose: Electrical System Alternator. And many

- manufacturers offer you the alternator for your car.

Make this shortcut and get your free info on Piecesauto24 . And fine your alternator.

Good luck!💪